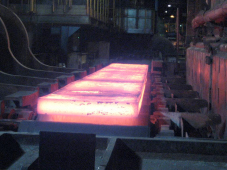

ProfilIST-T - Measuring Thickness and Width of Slabs and Thick Sheet Metal

The measuring system is used for highly precise thickness or/and width measurement of slabs and plates. For width measurement a material thickness of minimum 8 mm is necessary. The maximum length of the measured object can be up to 40 meters. The accuracy tolerance is constant and independent of the total measurement range. The measured value output will be visualized on a large display, while data transmission of measured values via EtherNet (TCP/IP). When integrating the sensors into a PLC only the laser sensors with ProfiBus or EtherNet TCP/IP interface are required. The measured value calculation is realized by the PLC.

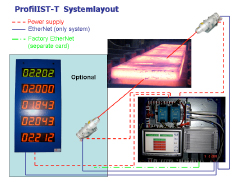

Design for an autonomous system of ProfilIST-T:

- 2 laser sensors with Ethernet TCP/IP

- Housing with industrial PC, operation via touch screen, Multi Switch, buffered voltage supply 24 VDC

- Large display

Software:

- Easy to use software

- User-friendly interface handled via touch screen

- Calibration is reduced to one time (commissioning), routine processes are running in the background

- Archiving the last 5 measured values

- Optional: transfer of data via Ethernet TCP/ IP to higher-level computer

Function of ProfilIST-T system:

- Detection of distances towards the material by laser sensors

- Transmission of the measured distance values to PC, calculating the width or thickness in real time

- Transfer of the measured values on display, forwarding the data to the control station

- Shows the last 5 measured values on the display

Calibration:

-

One-time calibration of the system by using reference measurement (commissioning) via test item

Considering the influence of environmental factors such as,

- High ambient temperatures

- Material temperatures up to 1,450 °C

- Dirt, dust

- Vibrations, shocks

- Different material surfaces