LoGas - Measuring Filling Levels in Gastanks

The measuring system LoGas is used for detecting filling levels in gas tanks within millimeter accuracy. Moreover it controls the horizontal alignment of the membrane in ongoing workflows. On reflector, the maximum distance measuring range can be several hundert meters. The tolerance accuracy is constant over the entire measuring area and is independent of the measuring length. For instance the sensors are connected to the PLC with a switch.

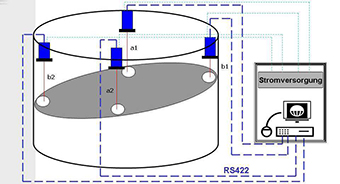

System design of the LoGas measuring system:

System design of the LoGas measuring system:

- 4 laser sensors LMC-J-00XX with Profibus , Ethernet TCP/IP or RS 422 via switch to PLC

Software:

- User-friendly PC software with application surface

Function of LoGas measuring system:

- Permanent detection of distances/ Monitoring the horizontal alignment of membrane with laser sensors

- Transferring of distance values to PC or PLC

- Monitoring the membrane during ongoing processes

Calibrating:

Calibrating:

- One-time calibration with a reference measurement

Considering of:

- ATEX–Zone